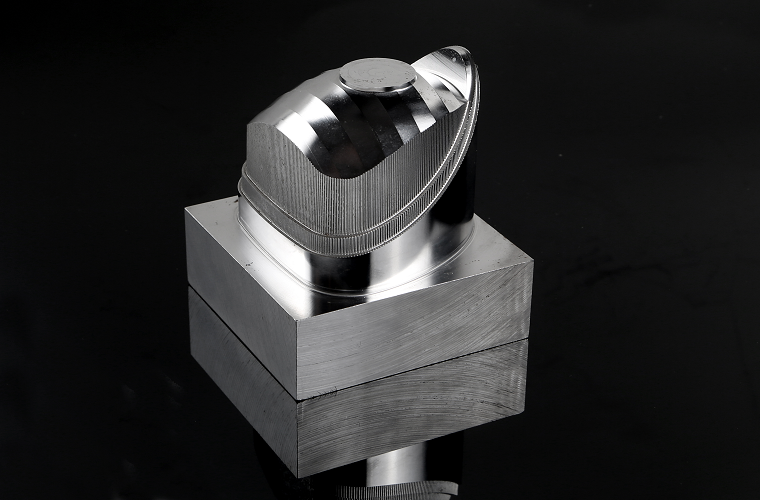

Custom Online Laser Cutting Services

From prototypes to on-demand production parts, get an instant quote for your metal or plastic projects with our online CNC machining services. Choose from 40+ materials, 10+ surface finishes. ISO 9001:2015, ISO 13485 certified.

- brightness_1Instant CNC quotes & detailed DFM

- brightness_1Tolerances down to 0.01mm (±0.0004″ )

- brightness_1Machined parts as fast as 1 day