Your Specifications, Our Products

Representative full custom/build‑to‑print on request. Each product is backed by documented inspection and traceability.

Rail Components

Precision electro‑mechanical and mechanical sub‑assemblies for rolling stock and wayside equipment, built strictly to drawing/spec.

Key features :

Interchangeability; fixture‑aided assembly; torque certificates; 100% visual/dimensional checks on CTQs.

Items covered :

Master Controllers - Functional control assemblies; endurance tested per ATP [FILL] - VCB Dampers - Damping sub‑assemblies; elastomers/metals per spec [FILL] - Air‑Suspension Hardware - Brackets, plates, housings; flatness & positional tolerances controlled

Options :

Coating systems per environment class; serialization/marking; packaging per fleet/region.

Documentation :

MTCs, PMI, inspection & functional test reports; PPAP on request.

Items covered :

Master Controllers (driver cab)

Hoist & Crane Hardware

High‑reliability clamp and winch latching assemblies for material‑handling and high‑mast applications.

Key features :

Wear‑resistant contact faces; controlled geometry on mating surfaces; corrosion protection; functional verification.

Items covered :

Rail clamps (storm/parking), clamp bodies & kits; winch latching mechanisms.

Testing :

Proof load tests [FILL]; torque/retention tests; DFT logs for coated parts

Documentation :

Inspection reports, test certificates, material traceability

Items covered :

Master Controllers (driver cab)

Stainless‑Steel Tubes & Pipes

Consistent weld integrity and surface finish, supplied with full documentation

Specs table :

Grades: 304/304L/316/316L [Add others] - OD Range: [FILL] - Wall Thickness: [FILL] - Lengths: [FILL] - Finishes: Mill / Pickled / Polished [FILL] - Tolerances: [FILL] (per standard or drawing)

Testing :

Hydro/air leak (as specified), dimensional checks, PMI

Documentation :

MTCs, compliance declarations, packaging specs.

Items covered :

Master Controllers (driver cab)

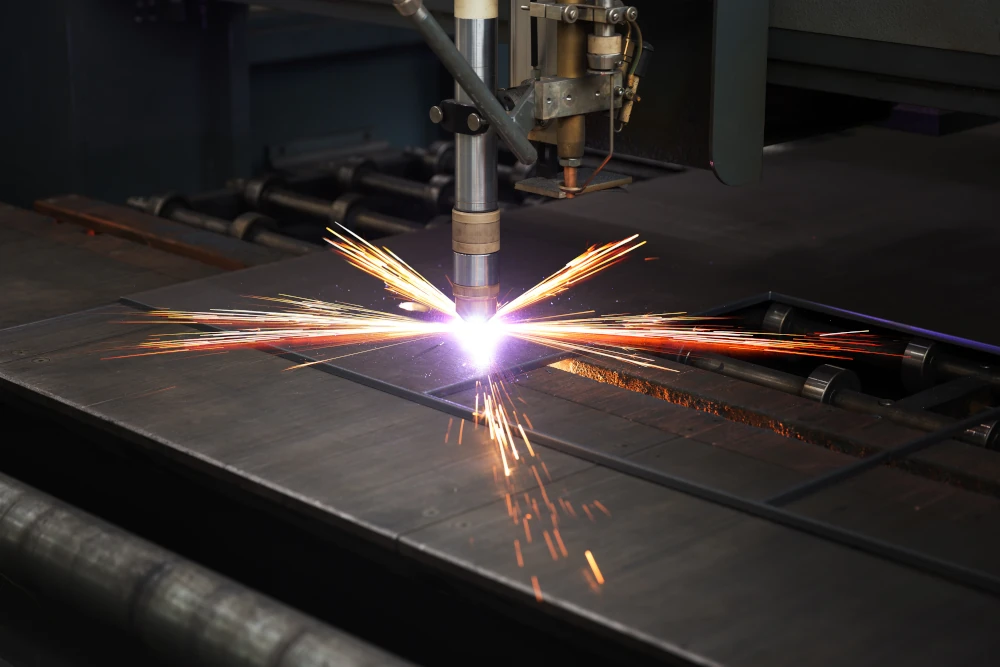

Build‑to‑Print / Contract Manufacturing

From RFQ to serial production with DFM feedback, controlled processes, and documented inspection.

Engagement model :

NDA → DFM/DFX review → Process planning → Pilot lot → Ramp‑up → Continuous improvement

Deliverables :

Control plan, FAI report, PPAP (if required), inspection reports, traceability

Items covered :

Master Controllers (driver cab)